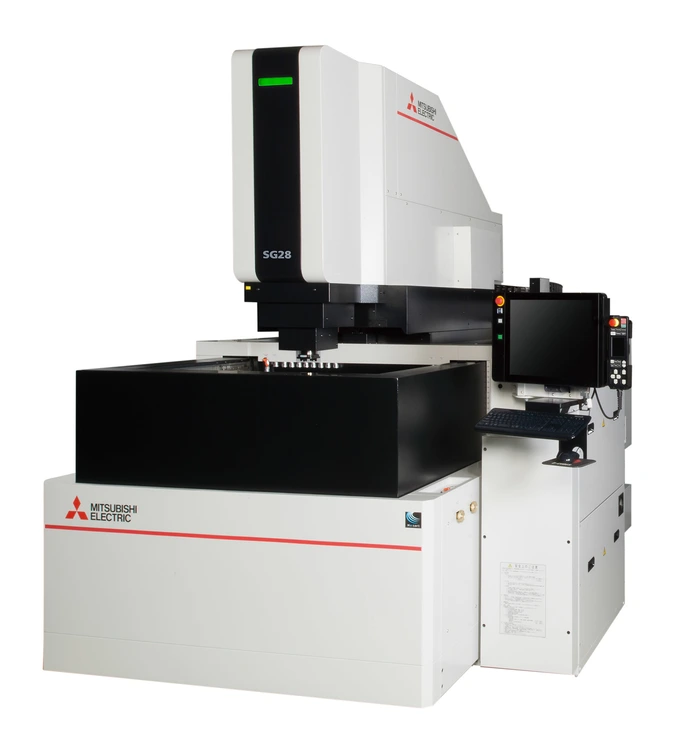

Unlock the potential of high-precision and high-productivity machining with the Mitsubishi SG28 Sinker EDM. Engineered to handle everything from fine, detailed shapes to large-sized components, this machine delivers exceptional accuracy and performance, making it a standout choice for demanding industrial applications.

The Mitsubishi SG28 is renowned for its enhanced rigidity and performance, thanks to a structural redesign of its cast. This improvement boosts its capability in handling middle to large area machining, efficiently reducing machining time and electrode wear. Equipped with Mitsubishi's proprietary Maisart AI technology, the SG28 excels in delivering automatic depth recognition and stable servo control, ensuring a consistently uniform surface finish across all projects.

Ideal for sectors that require meticulous detailing and dependable productivity, such as tool and die making or precision mold manufacturing, the SG28 sets new benchmarks in EDM technology. With its scalability and precise control, the Mitsubishi SG28 Sinker EDM is your solution to elevate production capabilities and achieve superior outcomes in high-precision machining tasks.

Machine travels (X x Y x Z) 650 x 450 x 400[mm]

Distance between table and electrode mounting surface 280-680[mm]

Max. electrode weight 200[kg]

Working tank method Automatic elevation tank

Working tank inner dimensions (W x D x H) 1100 x 810 x 450[mm]

Fluid level adjustment range (from top of table) 75-400[mm]

Table dimensions (W x D) 850 x 600[mm]

Max. workpiece dimensions (W x D x H) 1050 x 760 x 350[mm]

Distance between floor and top of table 895[mm]

Max. workpiece weight 2000[kg]

T-slot 5 slots at 14-100mm pitch

Total system weight 5600[kg]

Outline dimensions (W x D x H) 2620 x 2600 x 2745[mm]

Delivery machine size without ATC (W x H) 1990 x 2745[mm]

We use cookies to improve your experience. Privacy Policy.